An explosion at a caused a South Chattanooga, Tenn., industrial plant caused a fire that injured six employees.

Responders were called to the scene at 7:28 a.m, the Chattanoogan reported. Witnesses heard a loud explosion and could see smoke rising from the top of the Designed Alloy Products warehouse. Upon arrival, responders from the Chattanooga Fire Department were warned by workers not to use water due to materials and heat inside the furnace – which can reach 3,000 degrees, according to a worker. Firefighters instead used dry powder fire extinguisher materials to tackle the blaze. Within 25 minutes, crews had the fire under control.

Six workers for Designed Alloy Products were injured from the blaze, Times Free Press reported. Three were treated for smoke inhalation on the scene, while the others were brought to a local hospital for burn treatment. According to Chattanooga Fire Department Spokesman Bruce Garner, two suffered from minor burns while the third experienced third and second degree burns on almost 15 percent of his body. The injury, however, did not appear life threatening.

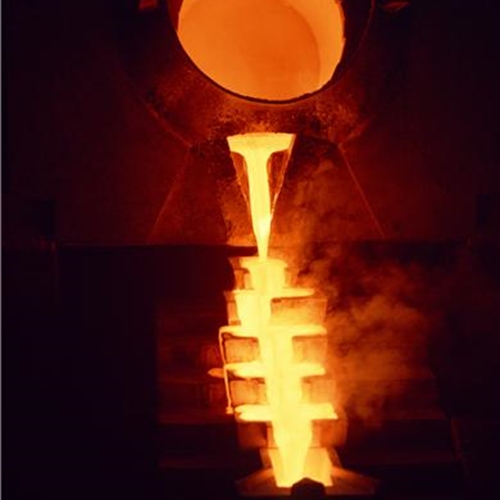

The Chattanooga company, located south of downtown near the Georgia border, is a producer of metal that makes certified ingots from recycled scrap metal. According to a worker, at the time of the explosion, employees were using the furnace to melt stainless steel.

Foundry Safety

The company is just one of many metal producers that are subject to foundry-related hazards. Use of hazardous materials and furnaces that operate at high temperatures expose foundry workers to unique risks, including heat exposure, silica inhalation, and fire hazards.

In an effort to raise awareness of the hazards, The Occupational Health and Safety Administration has signed and continually renewed an agreement with the American Foundry Society. According to OSHA's website, the alliance of the two organizations provides safety and health information and training on workplace issues. Along with addressing the need for personal protective equipment, the alliance released information about preventing foundry disasters.

In a document about fatalities in foundry workplaces, AFS outlines the most frequent causes of furnace explosions. If moisture is entrapped in molten metal, the report reads, "an explosion is inevitably produced. Regular checks must be made to ensure water is not present in the furnace area, and if moisture does arise, dry sand should be used to soak it up. OSHA reports that at least one employee died within the past five years when an internal water leak sprung from a water-cooled panel of an electric arc furnace and caused an explosion."

However, water can also enter furnaces in other ways, such as from moistened charge materials or from a leak in the facility's roof, windows or plumbing. Companies should perform regular checks to make sure the building is sealed.

The report also warns against explosions by other means – in particular, dust. If metal is cut or shaved in the warehouse, tiny particles could build on the floor, or in hidden areas above a suspended ceiling. If allowed to build up over time, dust can ignite from many different sources and produce a powerful explosion, even if the dust pile is less than an inch high. As the report reads, "water contacting molten metal accounts for 90% of the explosions that occur in a metalcasting facility, but the other 10% can be just as deadly."

In the case of Chattanooga, investigators have yet to reveal a cause of the fire. Estimates of damage have also yet to be determined.

Industrial Safety News brought to you by Safety Systems Technology, Inc., leaders in fire and gas detection.